your specialist for

port cranes, overhead cranes & gantry cranes

Regular inspections

essential for safety and operational reliability

NEDCRANES uses a special checklist for inspections and surveys:

- possible loss of production;

- necessary repairs or replacements;

- safety;

- environment;

- priority of the issues found in the inspection.

Prevent malfunctions with regular inspections

A badly-maintained crane installation is less reliable and more prone to malfunctions. If a lifting crane is part of an operational process, a malfunction may quickly cause a short or longer production stop. Scheduled inspections and/or tests will not only improve the reliability of the crane, also its safety will be increased.

Any defect which may have short-term or long-term negative effect on the safety and/or reliability of the crane installation will be marked with colour codes in the subsequent reports. Each item will include recommendations, so an well-considered decision can be made on repairing or replacing.

In consultation with you we will draw up an action plan focusing on the priorities identified in the inspection. This way we can fully unburden you. A next step could be to enter into an inspection or maintenance contract.

NEDCRANES is dealer of products from the standard range of the well-known brand GH Cranes & Components in the Netherlands. We offer similar inspectionservices.

Testing and other inspections

We carry out the inspections and testing of cranes in accordance with the working conditions and commodity law decrees and legislation.

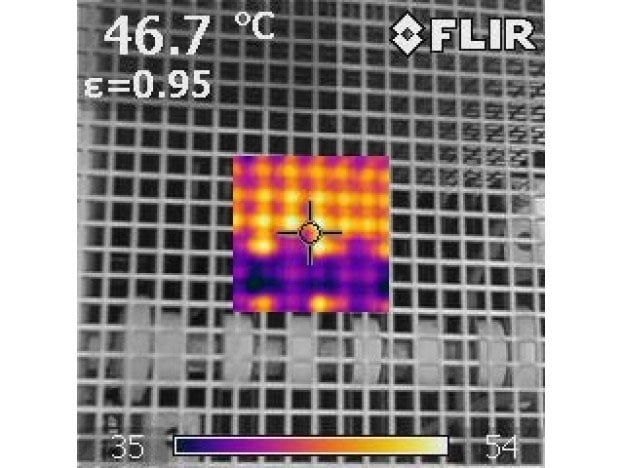

We also can help you to solve SWP (safe working period) problems. We notice that these questions are regularly asked during a consultation. Further you can contact us also for electrical inspections, thermography, an inspection for purchase or sale.

I have a question

Would you like us to contact you for more information, an advice without obligation or an appointment? Please fill in the form below and we will call or e-mail you.